| Ing. Petr Spacil - metalworking |

"Removed material - my added value" |

I offer you machining of small and middle-sized parts, and designing, constructing and production of mechanical assemblies.

My customers are for example producers of single-purpose machines and various prototypes, hobby CNC machine builders, modellers and many others.

I'm specialized on single-piece or small-lot production of parts made especially of aluminium alloys, regardless of the complexity.

Take a look at my

machine tools and

products

to determine whether I'm the right manufacturer for you.

My offer

|

Conventional turning Conventional turning |

|

including all threads

diameter up to 320 mm, length up to 900 mm

|

Single-piece or small-lot CNC turning Single-piece or small-lot CNC turning |

|

| with Asist 210×400 CNC |

Mass production Mass production |

|

of small simple turned parts up to ø16 mm

with that CNC lathe

|

|

|

|

CNC milling CNC milling |

|

CNC tool-room milling machine with both vertical and horizontal spindles

CNC drilling & milling machine

|

|

|

|

Conventional milling Conventional milling |

|

|

with vertical machine

with horizontal machine

|

|

Drilling, boring, thread cutting Drilling, boring, thread cutting |

|

Machining with rotary table and divider Machining with rotary table and divider |

|

|

radius milling

accurate angle-pitch holes

slotted parts etc.

|

|

Dividing material with band saws, Dividing material with band saws, |

|

|

| shape and angle cut-offs |

|

Core-save cut-off turning, curved drilling-off Core-save cut-off turning, curved drilling-off |

|

| other special methods of material-save dividing |

|

Dividing aluminium plates Dividing aluminium plates |

|

using manual circular saw (up to 10 mm thick)

|

|

Linear material dividing with disc-cutter Linear material dividing with disc-cutter |

|

|

| with horizontal milling machine (above 10 mm) |

|

Combined operations Combined operations |

|

milling and boring of turned parts

turning of non-rotary and asymmetric parts

|

|

Manual and machine edge beveling Manual and machine edge beveling |

|

Single-piece key-slotting in pulleys Single-piece key-slotting in pulleys

|

|

|

Materials I work with

|

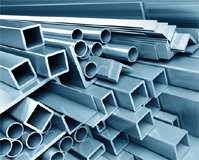

All aluminium alloys, dural All aluminium alloys, dural |

|

|

| also pieces cut with water jet, alu-castings |

|

Construction steels, free-cutting steel Construction steels, free-cutting steel |

|

laser-cut pieces, weldments,

threaded rods, various semiproducts

|

|

Non-ferrous metals - brass, bronze, copper Non-ferrous metals - brass, bronze, copper |

|

|

|

All technical plastics All technical plastics |

|

|

| nylon, teflon, plexiglass, polycarbonate etc. |

|

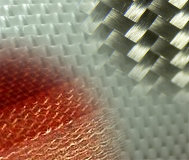

Composite materials Composite materials |

|

| textite, pertinax, fiberglass, carbon |

|

Grey cast iron, wood - only rarely Grey cast iron, wood - only rarely |

|

|

The accuracy |

|

|

By default, I work with the accuracy of 0.05 mm. If necessary, I'm usually able to keep the accuracy of 0.01 mm.

On the other hand, it is difficult to keep the accuracy under 0.2 mm for the dimensions above 500 mm.

During the production process, I also take care about other parameters and tricky things such as squareness,

angle precision, parallelism, roundness, centricity, unwanted conicalness, inner edge sharpness,

surface quality etc. The goal is that the final part must always satisfy all the requirements for

functionality, and also troublefree assembly, usage safety and appearance.

|

What I can't do

My technical equipment is not suitable for the following jobs. That's why I can't offer them as a standalone order.

However, some of these jobs can be done as a partial task within a larger project.

Providing subdeliveries (laser-cutting, anodizing) is only meaningful when combined with further work I can do for you.

|

Machining of stainless steel, titanium, Machining of stainless steel, titanium, |

|

|

| hardened and other materials difficult to machine |

|

Flat and round grinding, Flat and round grinding, |

|

| commercial tool sharpening |

|

Producing cog-wheels Producing cog-wheels |

|

|

|

Polishing, sanding, anodizing Polishing, sanding, anodizing |

|

|

| and other surface treatments |

|

Hardening and other heat treatments Hardening and other heat treatments |

|

Welding, point welding Welding, point welding |

|

|

| and other locksmith works |

|

|

Bending metal sheets, rods, tubes, Bending metal sheets, rods, tubes, |

|

|

| punching, forming |

|

Laser cutting from sheet metal Laser cutting from sheet metal |

|

| water-jet cutting |

|

Precise measuring, calibrating, balancing, Precise measuring, calibrating, balancing, |

|

material inspections a analysis

|

|

Conventional turning

Conventional turning

Machining of stainless steel, titanium,

Machining of stainless steel, titanium,